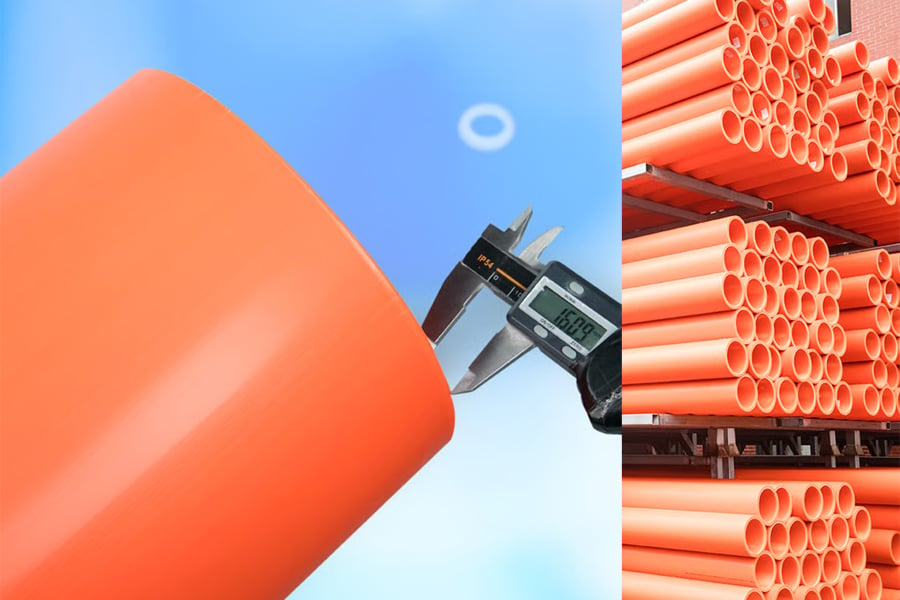

Introduction: The Difference Between MPP and PVC

When it comes to choosing the right material for your construction projects, understanding the differences between Multi-Purpose Polypropylene (MPP) and traditional Polyvinyl Chloride (PVC) can help you make an informed decision. Both materials have unique properties that make them suitable for various applications, but they also have distinct advantages and disadvantages.

Durability and Longevity

MPP is a highly durable material that is resistant to corrosion, abrasion, and UV exposure, making it ideal for outdoor applications. In contrast, while PVC is also durable, it is more prone to cracking and fading over time, especially when exposed to harsh environmental conditions. This makes MPP a better choice for long-term projects that require high durability.

Cost-Effectiveness

When it comes to cost, PVC is generally more affordable than MPP, making it a popular choice for budget-conscious projects. However, the long-term durability of MPP may offset its initial higher cost, as it may require less maintenance and replacement over time. Consider your budget and the expected lifespan of your project when deciding between MPP and PVC.

Environmental Impact

MPP is a recyclable material that can be reused in other applications, making it a more environmentally friendly option compared to PVC. PVC, on the other hand, is known for its negative environmental impact during production and disposal, as it releases toxic chemicals when burned. If sustainability is a priority for your project, choosing MPP over PVC may be the better choice.

Flexibility and Versatility

One of the key advantages of PVC is its flexibility, which makes it easy to work with and mold into various shapes. However, MPP is also a versatile material that can be customized to fit specific project requirements. Consider the flexibility and versatility of each material based on the unique needs of your project.

Installation and Maintenance

Both MPP and PVC are relatively easy to install and require minimal maintenance compared to other materials. However, MPP is known for its low friction coefficient, which can reduce the risk of blockages and increase the efficiency of fluid flow in piping systems. Consider the ease of installation and maintenance when choosing between MPP and PVC for your project.

Chemical Resistance

MPP is resistant to a wide range of chemicals, making it a suitable choice for applications that require exposure to corrosive substances. PVC also has good chemical resistance, but it may not be as robust as MPP in some situations. If your project involves handling chemicals, consider the chemical resistance of MPP and PVC carefully.

Temperature and Weather Resistance

Both MPP and PVC have good temperature and weather resistance properties, but MPP has a higher melting point, making it more suitable for extreme temperature conditions. PVC may soften or deform at high temperatures, which can affect its structural integrity. Consider the temperature and weather conditions of your project location when choosing between MPP and PVC.

Fire Performance

When it comes to fire performance, MPP is a self-extinguishing material that does not support combustion, making it a safer option compared to PVC, which releases toxic fumes when burned. If fire safety is a concern for your project, choosing MPP over PVC may provide added peace of mind.

Conclusion: Making the Right Choice

Overall, the choice between MPP and traditional PVC depends on the specific requirements of your project, including durability, cost, environmental impact, flexibility, installation, maintenance, chemical resistance, temperature resistance, weather resistance, and fire performance. By considering these factors and comparing the properties of MPP and PVC, you can make an informed decision that meets your project needs.