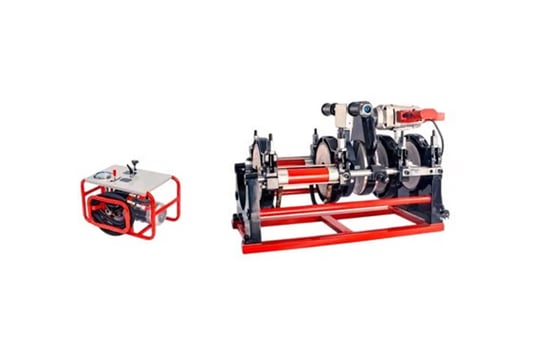

Overview of HDPE Equal Tee Butt Fusion FittingsHDPE Equal Tee Butt Fusion Fittings are essential components in polyethylene piping systems, used to join three pipe sections of equal diameter at a 90-degree angle. Made from high-density polyethylene (HDPE), these fittings provide durable and leak-free connections, making them ideal for a wide range of industrial, municipal, and agricultural applications. Their design ensures uniform distribution of flow, playing a critical role in fluid transport systems.Material Properties of HDPE in Equal Tee FittingsThe HDPE material used in Equal Tee Butt Fusion Fittings offers exceptional chemical resistance, flexibility, and impact resistance. These properties make HDPE a preferred choice for harsh environments, including corrosive soil or chemically aggressive media. The robustness of HDPE enables fittings to withstand extreme weather conditions, mechanical stress, and long-term environmental exposure without degradation.Butt Fusion Welding Process ExplainedButt fusion is a thermoplastic welding technique employed to join HDPE Equal Tee Butt Fusion Fittings seamlessly to pipes. In this process, the ends of both the fitting and pipe are heated and then pressed together to form a strong, homogeneous joint. This method eliminates the need for additional adhesives or mechanical connectors, enhancing the joint's strength and reliability while maintaining full bore flow within the piping system.Applications in Water Distribution SystemsHDPE Equal Tee Butt Fusion Fittings are widely utilized in potable water distribution networks due to their non-toxic nature and resistance to corrosion. The fittings ensure efficient distribution and direction of water flow in pipelines, enhancing system performance and reducing maintenance needs. Their leak-tight fusion joints prevent water loss, representing an economical and environmentally friendly solution for municipal water management.Role in Gas Distribution PipelinesNatural gas and other gaseous fuels are safely transported using HDPE Equal Tee Butt Fusion Fittings, which provide high-pressure resistance and secure joint integrity. The fittings’ ability to withstand thermal and mechanical stresses reduces the risk of pipeline failure. Their seamless fusion welding also offers excellent leak prevention, a critical aspect for safety in gas distribution infrastructure.Benefits of Equal Tee Design in HDPE FittingsThe equal tee configuration ensures all three branches maintain the same diameter, which optimizes flow dynamics and reduces turbulence. This design facilitates smooth fluid transition and system balancing in complex piping layouts. It is invaluable in systems requiring symmetrical flow distribution, such as irrigation networks or industrial fluid processing plants.Installation Advantages and EfficiencyInstallation of HDPE Equal Tee Butt Fusion Fittings is relatively straightforward when compared to other fitting methods. The butt fusion process allows onsite assembly without extensive excavation or use of heavy equipment, reducing labor costs and time. Furthermore, the strong fusion joints eliminate the need for additional clamps or sealing materials, streamlining the installation process.Longevity and Maintenance ConsiderationsDue to HDPE’s intrinsic chemical resistance and toughness, Equal Tee Butt Fusion Fittings exhibit exceptional longevity with minimal maintenance. The butt fusion joints are permanent and resistant to leaks, drastically lowering repair frequency. Additionally, HDPE fittings show excellent resistance to biological growth and scaling, further enhancing the lifespan and performance stability of piping systems.Compliance with Industry StandardsHDPE Equal Tee Butt Fusion Fittings conform to international standards such as ASTM F1055, ISO 4427, and other local certifications. These standards ensure the fittings meet rigorous requirements for pressure ratings, dimensional accuracy, and material quality. Compliance guarantees compatibility with existing piping infrastructure and assures system reliability for engineers and contractors.Environmental and Economic ImpactUsing HDPE Equal Tee Butt Fusion Fittings contributes positively to sustainability efforts by reducing resource consumption and minimizing leaks that lead to water loss or environmental contamination. The fittings’ durability also means fewer replacements and less waste generation. Economically, their cost-effectiveness and ease of installation lead to lower overall project costs, making them a valuable choice for utility planners and industrial engineers alike.Quote Inquirycontact us